Into the cloth expanding centering device

The transverse plate type of device provided with adjustable angle expanding device, in the cloth into the first fully without wrinkles, curling expanding, to bring users the best expanding in effect.

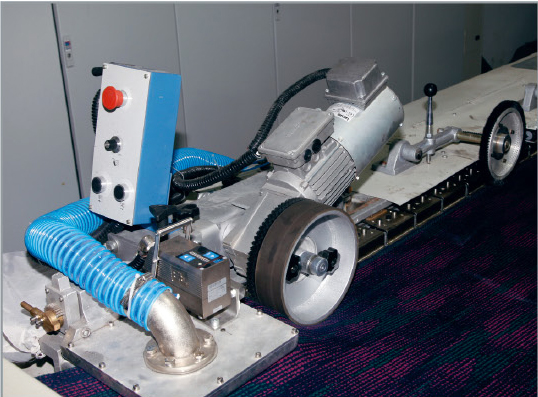

Cloth feeding combination device

MR203 type energy-saving environment-friendly hot air stenter

Shaping machine

Cloth feeding combination device is composed of a cloth feeding frame, expanding on the device, rolling cars, speed synchronization device, photoelectric ABB finishing apparatus (optional). Its role is to cloth under low tension are expanding on the post, by the rolling vehicle for dehydration, the cloth to add finishing process, between the rolling car and photoelectric weft fabric tension device, the speed synchronization device for accurate control, photoelectric weft device effectively corrected the deformation and weft, weft cloth produced by arc in the process, so as to achieve the requirements of all kinds of craft fabric needed in the cloth before the needle.

Composed of two solid roller, a cylindrical solid roller, the other one is the drum solid roller, the actuator back in uniform pressure, adjust the required pressure, collation and dehydration of the cloth. Composed of two solid roller, a cylindrical solid roller, the other one is the drum solid roller, the actuator back in uniform pressure, adjust the required pressure, collation and dehydration of the cloth.

MR203 type energy-saving environment-friendly hot air stenter

Shaping machine

Control console

In accordance with the operating table body engineering design, reduce the labor intensity of the operator

is simple and user-friendly operation panel design, easy control of the operation efficiency of

visual design concept, to understand the running status of equipment

MR203 type energy-saving environment-friendly hot air stenter

Shaping machine

Oven system

The insulation panel is made of 150MM thick high density insulation materials, the oven heat loss in the lowest state

each insulation panel is connected with the frame and shutter, can smoke screen are respectively provided with effective sealing device for

efficient energy-saving oven design, the overall height is 160MM, the low heat and can meet all kinds of technical requirements

oven cloth are import gas shielding device

Overfeeding

Super feed between the roller and the needle chain over feeding adjustment range (-30%~+80%), to meet the various needs of the fabric overfeed ratio of about

on the needle over feed rate can be set individually for

compressed air show edge device ensures the selvage needle before fully expanded